I-Redar ligama eliqhelekileyo lokuvalwa kwentsimbi eshushu. Ibakala lebhani yentsimbi eqingqiweyo eqingqiweyo ene-HRB kunye neyona ndawo iphantsi yenqanaba lebakala. H, R, kwaye iileta zokuqala zamagama mathathu, ezidliwayo, ezishushu, iiribula nezivayo, ngokulandelelana.

Ibha yentsimbi eshushu eshushu yahlulwe yangamaBanga amathathu: HRB335 (IBakala lakudala lingama-20mns), iBakala lesithathu HRB400 (IBakala lakudala (iBanga laBadala liyi-20mnsnb, kunye neBanga lesine le-HRB500.

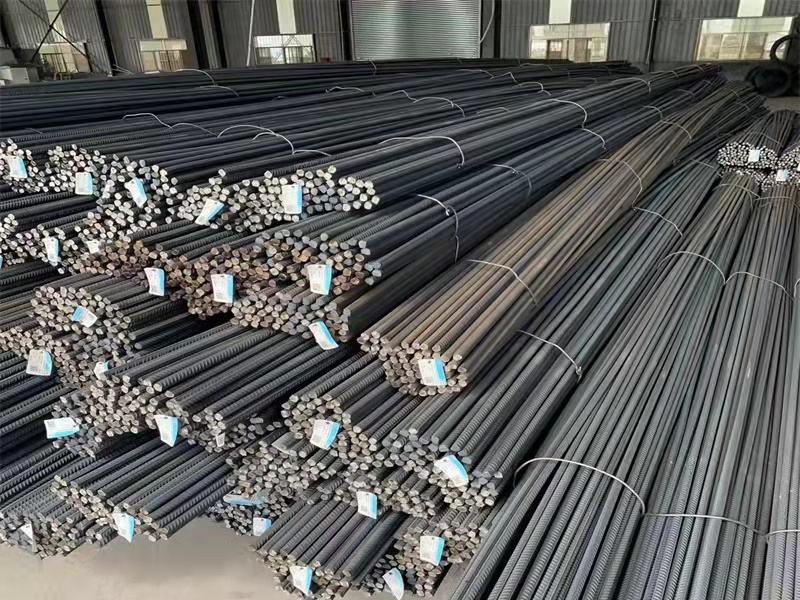

I-remorbar yibar yensimbi yentsimbi kumphezulu, ekwabizwa ngokuba yi-ribebebe yentsimbi, ihlala ineembambo ezi-2 ze-2 elide kunye neembambo ezihamba ngeenyawo kunye neembambo ezinqamlezayo zisasazwe ngokulinganayo. Ubume bombala oguqukayo yibala, i-herringbone kunye nemo ye-crescent. Ivezwe kwiimilimitha zobuncinci. Ububanzi be-Rible ye-Ribbed Bar ihambelana ne-diameter yonyulo yebhanti ejikelezayo yecandelo elilinganayo. Ububanzi be-repulball yi-8-50 mm, kwaye iidayimitha ezinconyiweyo ziyi-8, 12, 20, 25, 32, kunye ne-40 mm. Imivalo yensimbi yensimbi ikakhulu iphantsi koxinzelelo olunamathele kwikhonkrithi. Ngenxa yesenzo seeribs, imivalo yentsimbi ye-ribebe inabantu abaninzi abanobuchule obukhulu bekhonkco ngekhonkrithi, ngenxa yoko banokumelana nesenzo semikhosi yangaphandle. Imivalo yentsimbi ye-ribebe isetyenziswe ngokubanzi kwimibutho eyahlukeneyo yokwakha, ngakumbi, inzima, imbiza ehamba ngeenyawo enqabileyo nenyukayo.

Ukuphinda kwenziwe zii-mills ezincinci eziqengqelekayo. Iindidi eziphambili ze-mills ezincinci eziqengqelekayo zezi: Ukuqhubeka, ukuqhubeka kunye nomqolo. Uninzi lwezinto ezintsha kwaye zisebenzisa ii-mills ezincinci eziqengqelekayo emhlabeni ziqhubeka ngokupheleleyo. I-Remouse Redar Mills i-roll-geness ehamba ngesantya esiphezulu sokuhamba ngesantya esiphezulu kunye ne-4-slice slice ephezulu ye-repure.

I-billlet esetyenziswe kwi-milling encinci eqhubekayo yi-Billet eqhubekayo ye-billet, ubude becala ngokubanzi yi-130 ~ 160mm, ubude buziimitha ezili-12 ngokubanzi, kunye nomzimba we-billet enye yi-1.5 ~ 3 iitoni. Uninzi lwemigca eqengqelekayo icwangciswe ngokuthe nkqo kwaye ngokuthe nkqo, ukufezekisa i-torsion-free iqengqele emgceni. Ngokutsho kwenkcazo yeBillet eyahlukileyo kunye nesayizi yemveliso egqityiweyo, kukho i-18, 20, 22, kunye nemizila emi-24, kwaye i-18 yeyona nto iphambili. I-bar iqengqeleka ikakhulu kwiinkqubo ezitsha ezinjengokwenza izitya zokufudumela, ukuphoswa kwamanzi eziphezulu, ukuchuma okuphantsi, kunye nokuqengqeleka okungapheliyo. Ukuqengqeleka okuthe tyaba kunye nokuntywila okuphakathi kuyaphuhlisa kwicala lokuziqhelanisa neebhanti ezinkulu kunye nokuphucula ukuchaneka kokuvuka. Ukuchaneka okuphuculweyo (isantya (ukuya kwi-18m / s). Inkcazo yemveliso ngokubanzi ф10-40mm, kwaye kukho ne-¶6-32mm okanye ¶12-50mm. Amabakala ensimbi aveliswa, i-carbon yekhabhoni yekhabhoni kunye nentsimbi ephantsi ye-ALTEY efunwa ngokubanzi yintengiso; Isantya esiphezulu sokuqengqeleka sili-18m / s. Inkqubo yayo yemveliso imi ngolu hlobo lulandelayo:

Ukuhamba kwesithando somlomo →I-Milling Milling → I-Mill Rill Goming → Ukugqitywa kwesigidi → isixhobo sokupholisa amanzi → Ibhedi yokuphola Ifomula yeFosting Countral Ifomula: Ububanzi bezinto zangaphandle

IXESHA LOKUQALA: APR-26-2022