Indlela yemveliso kunye nenkqubo yentsimbi eqingqiweyo yensimbi yensimbi

Indlela yemvelaphi:

Kwintengiso yesaphulelo ekhoyo, i-HRB400e Akhawunti ngaphezulu. Eyona ndlela yokomeleza i-microal yeyona ndlela iphambili yokuvelisa i-HRB400E ehlabathini. I-microalloy ikakhulu i-dadadium alloy okanye i-niobium alloy, etya kakhulu imithombo yesakhiwo minyaka le. Ngenxa yemirhumo yezimbiwa ezinomda oqukethe i-Adadium ne-Niobium, ukuhanjiswa kwezi zinto zabelayo ziqinile. Ke ngoko, ukuba umxholo we-HRB400e bar unokuncitshiswa, iya kuvelisa izibonelelo ezinkulu zoqoqosho nezentlalo.

Kwi-tekhnoloji esele ikho, intambo ye-wire-roll windows engasebenziyo ngaphandle kokunciphisa kwaye i-shall gesing ruct yamkela i-Alb400E, kunye nepesenti enkulu ye-dadadium yi-0.045%.

I-Chinese Patent CN104357741A iveza uhlobo lwe-HRB400E -ie-Gat-Geage-Poight Spire-Poight kunye neMveliso yeMveliso yeMveliso. Through the method, the finished product is produced by a reducing and sizing rolling mill, which can ensure that the finishing rolled steel is rolled at a low temperature of 730~760 ℃ to obtain For finer grains, this method is not suitable for production lines without reducing sizing mills. I-Chinese Patent CN110184516A ichaza indlela yokulungiselela uWire φ6mm ~ ~ hrb400e egutyungelweyo. Ngoncedo lokuqengqeleka kwezixhobo, ukuqengqa kweqondo lobushushu eliphantsi kuqala kwiqondo lobushushu lokufudumeza, kwaye imveliso ngaphandle kwe-microalloile ifezekisiwe. Ukungancediki kwale ndlela kukuba ukusebenza kwamandla kunye nezixhobo zemoto yezixhobo zokuqengqeleka kunye nephakathi zemveliso yezixhobo, kunye nokunyusa iindleko zolondolozo lwezixhobo, kunye nokunyusa indleko ze-wire φ6mm ~ HRB400E Coil Iveliswe ngale ndlela yintsalela. Ubungakanani obungapheliyo, kunzima ukuqinisekisa inqanaba lomgangatho wokusebenza.

IZIBHENO ZOBUCHULE:

Ukuyilwa okwangoku kujolise ekunikezeleni indlela yokuvelisa imixokelelwane yentsimbi evuthiweyo, ngakumbi indlela yokuvelisa imitya ebiyelwe i-wire φ8 ~ ~ ~ ~

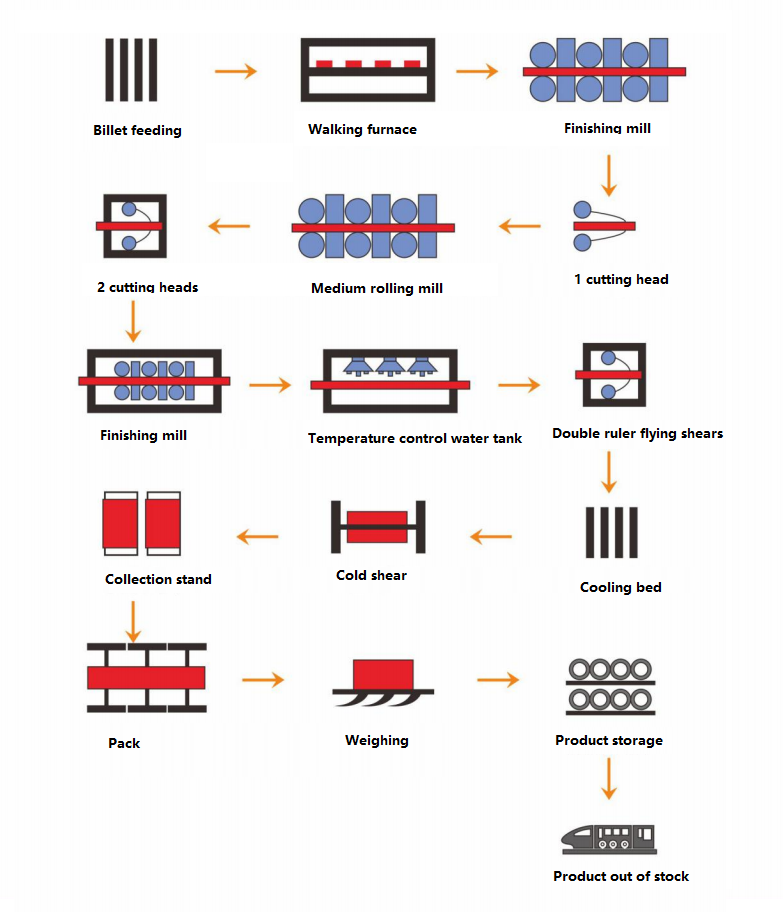

Iskimu sobuchwephesha bokutshiswa kwangoku:

Indlela yemveliso eqingqiweyo ye-ribed yentsimbi, ukucaciswa kwe-will yentsimbi yentsimbi yentsimbi yi-φ8 ~ ~10mm, i-roll-roll-qengqesha - ukugqitha - ukugqitha - ukugqitha - ukuphola-ukuqhutywa kwe-roller-roll-rol-row-upral-upral. Ipesenti yobuninzi yekhemikhali yentsimbi yentsimbi yintsimbi ye-C = 0.20% ~ 0.0.045%, i-0.045%, i-0.045%, i-0.012%, ezinye zezinto ezingenakuthintelwa; Amanyathelo aphambili enkqubo abandakanya: Ubushushu bothando yi-1070 ~ 1130 880 ℃; Ukubeka ubushushu 845 ~ 875 ℃; Ubushushu bokugqibela bokuhambisa bungaphantsi kweqondo lobushushu be-revyrystalling yendawo yokufumana amandla; Ukupholisa okukhawulezayo nge-fan kwitafile epholileyo ye-roller, ivolumu yomoya yi-100%; Iqondo lobushushu lesiciko lingama-640 ~ 660 ℃, iqondo lobushushu le-Heightres orrisol luyi-600 ~ 620 ℃, kwaye ixesha kwifilimu yokugcina ubushushu yi-45 ~ 55s.

Umgaqo wokuyilwa: Kuluhlu lobushushu lwe-840-880 ℃, ingqumbo ye-austedite ikhutshiwe ngokuqengqeleka, kodwa i-regrystald yenzekile. Nangona kunjalo, amaqela enzala aveliswa kwi-Issuins, kwaye iziphelo zeebhendi zokusebenza zihlala zikwimida yengqolowa, kwaye zikwakhona neebhendi zengqolowa kwimida yokudla okuziinkozo ukwahlula-hlula iinkozo ze-alondite. Ngexesha lotshintsho ukusuka kwi-austerite yokufana, zombini imida yokudla okuziinkozo e-Elonyite kunye neNdawo yokuDityaniswa kweMida yeNdawo yokuDityani yeMida njengeendawo eziFumiri zoFertire, ezikhokelela ekuphuculeni utshintsho emva kwenguqu emva kwenguqu. Amaqondo obushushu asezantsi aqengqeleka kwi-Mill yokuGqibela kunciphisa umthwalo oqengqelekayo wezinto ezikrwada kwaye ezijikelezileyo kunye neeMills eziqengqelekayo kunye nokugqibezela abantu kwaye kunyusa ubomi benkonzo yezixhobo.

Iziphumo eziyingenelo zoyilo zimi ngolu hlobo lulandelayo: ngokongeza isixa-mali esincinci se-v se-microalloy, amandla esivuyiweyo siphuculwe, kwaye senza i-carbides, kwaye idlale indima yokomeleza i-rocimity. I-nquire eshushu eshushu eqingqiweyo inamandla e-then-700-700pa, amandla esivuyiweyo ye-420-555 i-40MPA, kunye ne-AGRPA> 10%, eqinisekisa ukuba umda owoneleyo. Amandla esiveliso sisizinzo, kwaye ireyithi yomgangatho wokusebenza ingaphezulu kwe-99%. Ukuqulunqwa kwengqondo kusombulula ingxaki eqengqelekayo ye-twist eqengqelekayo ukwenza ubushushu obusezantsi, kunciphisa indleko kwisakhiwo sokuqinisekisa ukuba amandla okuvelisa ancitshiswa, aze azise malunga nezibonelelo eziphezulu zoqoqosho.

Iinkcukacha ezineenkcukacha

Umxholo wolondolozo lwangoku luchazwe apha ngezantsi ngokudibeneyo kunye ne-embomitha.

Indlela yemveliso yeqela le-wire ephezulu φ8mm ~ ~10mmhrb400e iqhinga eligxekayo. Inkqubo eqengqelekayo: 45 ~ 55s, kwaye ipholile ngokwemvelo. Ukwenziwa kweekhemikhali zentambo ye-wire ye-ECODDODE ye-ECODDODONORY YOKWENZIWEYO KWITheyibhile 1, kunye neempawu zobuchwephesha ze-wire ye-wire ye-wire ye-ECODDORE iboniswe kwiTheyibhile 2.

Ukuqulunqwa kwamachiza (i-WT%) ye-wire rod yomzekelo wetafile

Itheyibhile 2 Iipropathi zoomatshini womzekelo we-wire rods

Amandla esivuyiweyo ye-wire ephezulu φ8mm ~0mmhrb400e iqhekeza lemigca eveliswe yi-420 ~ 500MPA, i-ADT ingentla kwi-1%, kwaye i-AGT SITAPRAPIC iphela kwaye i-Pearlic iFreyiti iphela kwaye i-Pearlic iphela. , ukusebenza okuzinzileyo, amandla omzimba obaneleyo kunye nomda we-arm, impumelelo yale nkqubo ibaluleke kakhulu ekunciphiseni iindleko zemveliso kunye nokwandisa inzuzo yemveliso ye-torsion enemigca endala.

Iimpawu zobugcisa:

I-1. Indlela yemveliso ye-ribed eshushu eshushu, i-bire rod i-φ8mm ~ 10mms, i-rollecy-roll-roll-roll-roll-roll-roll-roll-roll-qengqesha - ukugqitha - ukugqitha - ukugqitha - ukugqitha kwe-roll-rating yentsimbi yentsimbi c = 0.20% ~ 0.25%, i-0.40% ~ 0.045%, i-0.045%, i-0.045%, ezinye zizinto ezingenakuthintelwa; Amanyathelo aphambili enkqubo ibandakanya: iqondo lobushushu liyi-1070 ~ 1130 ° 230 ° 230 ° 110 ~ 1000 ° 2000 ° 2 ° 2 ° 2 ° 2 ° 2, kunye nokuqengqeleka kwenziwe. Iqondo lobushushu yi-840 ~ 880 ℃; Iqondo lobushushu liyi-845 ~ 875 ℃; Ubushushu bokugqibela bokuhamba bungaphantsi kweqondo lokushisa le-ausrystall Ipholile ngokukhawuleza yi fan kwitafile epholileyo epholileyo, kwaye ivolumu yomoya yi-100%; Itheyibhile yeRoll ifakwe ngokuvalela i-inshurensi yokufakelwa, iqondo lobushushu lokungena kwi-inshoard luyi-640 ~ 620 ℃, kunye nexesha kwi-R 10.0s.

Isishwankathelo sobugcisa

Indlela yemveliso eqingqiweyo ye-ribed yentsimbi, i-wio eshushu ye-rod ye-rod rod yi-φ10mm, i-0.40%, i-0.045%, i-0.045%, v = 0.020%, Ezinye izinto zininzi kwaye zingenakuthintelwa izinto ezingenakuthintelwa; Inkqubo eqengqelekayo: Iqondo lobushushu lingama-970 ~ 1000 ℃, ukugqiba ubushushu obuqengqeleka yi-840 ~ 880 ℃; Iqondo lobushushu liyi-845 ~ 875 ℃; Ubushushu bokugqibela bokuhamba bungaphantsi kweqondo lobushushu be-ausrystalling yengingqi ye-austentite; %; Emva kokuvala isiciko se-roller, iqondo lobushushu lokungena kwi-inshorensi ye-inshontes yi-640 ~ 620 ℃, kwaye ixesha kwi-Rids I-RICE liyi-45 ~ 55s. Ngokongeza isixa-mali esincinci se-VALTY kunye nokugqiba ukugqitha kubushushu obuphantsi, ukutshintshwa akuqinisekisi kuphela ukusebenza kwezixhobo, kodwa kunciphisa umxholo we-Afloy kunye neendleko.

IXESHA LOKUQALA: AUG-30 ukuya ku-2022